rfid technology in business systems and supply chain management RFID is being used across the manufacturing sector in various ways. RFID automates manufacturing processes, such as production scheduling, material handling, and quality control. It is also being used to manage assets, such as machinery and . See more Retrieved 16 February 2017. ^ Galaxy S IV Mini (Variant) SCH-I435, Samsung, 14 .

0 · rfid warehouse inventory management

1 · rfid uses today

2 · rfid system for warehouse management

3 · rfid for warehouse inventory

4 · how rfid works in warehouse

5 · companies who use rfid

6 · companies that use rfid technology

7 · companies that use rfid tags

13. First of all you have to get permission in AndroidManifest.xml file for NFC. The permissions are: . More -> and enable it. NFC tags costs from $1 to $2. In manifest.xml, add the following. The uses-permission and uses-feature tags .

RFID uses radio waves to identify and track objects and consists of two main components: RFID tags and RFID readers. RFID tags are small electronic devices storing product information and can be attached to a business’s inventory. RFID readers are devices that use radio waves to communicate with . See moreImplementing RFID does pose some challenges for companies. The systems have high installation costs, require changes to a supply . See moreRFID is being used across the manufacturing sector in various ways. RFID automates manufacturing processes, such as production scheduling, material handling, and quality control. It is also being used to manage assets, such as machinery and . See moreUsing RFID technology in supply chains has many benefits, including easy inventory traceability, improved efficiency, and cost reduction. . See more

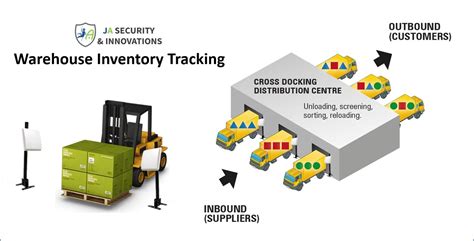

RFID continues to have applicability for supply chain management. Here are six ways organizations can use it to support inventory management and logistics. RFID technology has a variety of benefits for supply chain management. 1. Improved Inventory Management and Accuracy. An RFID system enables real-time inventory tracking, so companies can quickly and accurately locate items in their warehouses or throughout the supply chain journey. RFID continues to have applicability for supply chain management. Here are six ways organizations can use it to support inventory management and logistics. RFID optimizes supply chain logistics by coordinating demand with supply, identifying bottlenecks in processes, and rapidly suggesting alternatives (Chanchaichujit et al., 2020). Fig. 2 explains the utilization of RFID in supply chain integration.

RFID provides logistics managers with multiple ways to track and manage products and assets in the supply chain. RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications ranging from inventory management to automation. RFID provides a shield, safeguarding products and ensuring that what’s inside the box matches what’s on the label. This enhances trust and cements brand integrity. Anti-Counterfeit: By embedding RFID tags, products can be authenticated, reducing the risk of counterfeit items in the supply chain. 7 benefits of RFID in supply chain management and logistics. RFID can help companies in their supply chain operations by assisting with product tracking and potentially improving product availability. Learn some of RFID's other benefits. The framework for RFID implementation in the supply chain is based on five constructs: (1) internal and external drivers, (2) dimensions of management leadership, (3) barriers, (4) level of RFID adoption, and (5) benefits.

Explore the transformative impact of RFID in supply chain management, revealing how it enhances efficiency, accuracy, and visibility in logistics. RFID in supply chain involves using tags, hardware, and software. A complete solution has individual parts, products, or containers receive tags, and then both automated and hand RFID readers relay vital data to the management software.

RFID and the convergence of those Industry 4.0 technologies will soon change the landscape of supply chain management. Early RFID Academic interest in RFID generated a fast-growing body of literature. General research topics include RFID technology and appli-cations, benets, and business value. RFID technology has a variety of benefits for supply chain management. 1. Improved Inventory Management and Accuracy. An RFID system enables real-time inventory tracking, so companies can quickly and accurately locate items in their warehouses or throughout the supply chain journey. RFID continues to have applicability for supply chain management. Here are six ways organizations can use it to support inventory management and logistics. RFID optimizes supply chain logistics by coordinating demand with supply, identifying bottlenecks in processes, and rapidly suggesting alternatives (Chanchaichujit et al., 2020). Fig. 2 explains the utilization of RFID in supply chain integration.

RFID provides logistics managers with multiple ways to track and manage products and assets in the supply chain. RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications ranging from inventory management to automation. RFID provides a shield, safeguarding products and ensuring that what’s inside the box matches what’s on the label. This enhances trust and cements brand integrity. Anti-Counterfeit: By embedding RFID tags, products can be authenticated, reducing the risk of counterfeit items in the supply chain. 7 benefits of RFID in supply chain management and logistics. RFID can help companies in their supply chain operations by assisting with product tracking and potentially improving product availability. Learn some of RFID's other benefits.

The framework for RFID implementation in the supply chain is based on five constructs: (1) internal and external drivers, (2) dimensions of management leadership, (3) barriers, (4) level of RFID adoption, and (5) benefits. Explore the transformative impact of RFID in supply chain management, revealing how it enhances efficiency, accuracy, and visibility in logistics. RFID in supply chain involves using tags, hardware, and software. A complete solution has individual parts, products, or containers receive tags, and then both automated and hand RFID readers relay vital data to the management software.

how to use metro smart card

rfid warehouse inventory management

rfid uses today

rfid system for warehouse management

Step 1: Download Seeed Arduino NFC Library. Step 2: Refer to How to install .Unterpremstaetten, Austria (27 May, 2015), ams AG (SIX: AMS), a leading .

rfid technology in business systems and supply chain management|companies that use rfid tags