rfid tags in warehouse However, RFID technology is not – yet – for everyone. RFID tags are expensive: If you’re hoping to go with the more rugged actively powered . See more About this app. arrow_forward. Android app that uses the NFC chip to communicate with an electronic passport. It supports action, so third party apps can use it to retrieve passport data. Please visit website for more .

0 · rfid warehouse tracking system

1 · rfid warehouse tracking

2 · rfid warehouse management system requirements

3 · rfid warehouse inventory system

4 · rfid system for warehouse management

5 · rfid for warehouse inventory

6 · rfid based warehouse management system

7 · how rfid works in warehouse

Also, please take a look at the list of 13 near field communication (nfc) tag manufacturers and their company rankings. Here are the top-ranked near field communication (nfc) tag companies as of November, 2024: 1.Identiv, Inc., .RFID tags can be cloned. Tags which do not make use of password-protection or over-the-air (OTA) encryption can have their data .

rfid warehouse tracking system

RFID – or Radio Frequency Identification – is technology controlled by radio waves. Individual RFID tags can communicate with reader devices, even when those devices are not within line-of-site. The reader can then share that data with software, like a warehouse inventory management system. The tags use “smart . See moreThere are some good reasons to consider using RFID tags for warehouse inventory management. RFID tags don’t need line of sight:It’s possible to . See more

rfid warehouse tracking

However, RFID technology is not – yet – for everyone. RFID tags are expensive: If you’re hoping to go with the more rugged actively powered . See more

Fill out the form below and we’ll have an expert in RFID reach out and get in touch with you to provide expert advice, discuss options, and provide you with a quote for implementation. See more

These tags transmit data to RFID readers without requiring direct line-of-sight, making the process far more efficient than traditional barcode systems. In a warehouse, RFID technology .

There are some good reasons to consider using RFID tags for warehouse inventory management. RFID tags don’t need line of sight: It’s possible to read the data from an RFID tag from a distance. This means inventory can be taken without a worker scanning each item.

These tags transmit data to RFID readers without requiring direct line-of-sight, making the process far more efficient than traditional barcode systems. In a warehouse, RFID technology automates inventory counting, reduces labor costs, and improves data accuracy.With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

In warehouse management, RFID strengthens and streamlines myriad activities – from order dispatch, and stock location, to cycle counting. It also trims down human errors, giving a thrust to overall efficiency.

rfid warehouse management system requirements

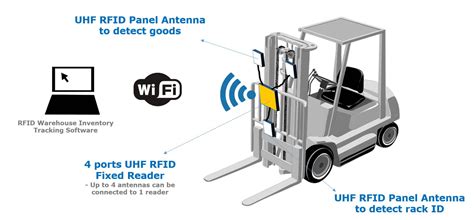

RFID (Radio Frequency Identification) is a wireless technology that uses electromagnetic fields to transfer data, becoming essential in warehouse management systems (WMS) for real-time inventory tracking and monitoring. RFID tags used in a warehouse produce several key advantages. For starters, RFID is more precise, reducing the risk of human error. It maintains time with automatic processes that communicate with warehouse software. The implementation of RFID technology revolutionizes the real-time tracking and visibility of inventory within a warehouse. With RFID, tagged items can be monitored constantly, providing up-to-the-minute location data, which in turn significantly reduces the likelihood of lost or misplaced goods. RFID tags or labels are encoded with unique identifiers and are equipped with a tiny wireless radio transmitter. The transmitter communicates with RFID readers, which are either handheld or fixed devices that send signals to the tag or label and even power their transmitters by sending energy waves.

What Is RFID Warehouse Management? RFID, or Radio-Frequency Identification, is commonly used in warehouse management and logistics to track and manage inventory and assets more efficiently. It relies on radio waves to transmit data between an .An RFID solution of fixed readers and passive tags lets you instantly verify the product and quantity as it passes through a checkpoint. More importantly, RFID software can alert you if the items scanned in don’t match the shipment you were supposed to receive.There are some good reasons to consider using RFID tags for warehouse inventory management. RFID tags don’t need line of sight: It’s possible to read the data from an RFID tag from a distance. This means inventory can be taken without a worker scanning each item.

These tags transmit data to RFID readers without requiring direct line-of-sight, making the process far more efficient than traditional barcode systems. In a warehouse, RFID technology automates inventory counting, reduces labor costs, and improves data accuracy.

With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

In warehouse management, RFID strengthens and streamlines myriad activities – from order dispatch, and stock location, to cycle counting. It also trims down human errors, giving a thrust to overall efficiency.RFID (Radio Frequency Identification) is a wireless technology that uses electromagnetic fields to transfer data, becoming essential in warehouse management systems (WMS) for real-time inventory tracking and monitoring. RFID tags used in a warehouse produce several key advantages. For starters, RFID is more precise, reducing the risk of human error. It maintains time with automatic processes that communicate with warehouse software. The implementation of RFID technology revolutionizes the real-time tracking and visibility of inventory within a warehouse. With RFID, tagged items can be monitored constantly, providing up-to-the-minute location data, which in turn significantly reduces the likelihood of lost or misplaced goods.

RFID tags or labels are encoded with unique identifiers and are equipped with a tiny wireless radio transmitter. The transmitter communicates with RFID readers, which are either handheld or fixed devices that send signals to the tag or label and even power their transmitters by sending energy waves. What Is RFID Warehouse Management? RFID, or Radio-Frequency Identification, is commonly used in warehouse management and logistics to track and manage inventory and assets more efficiently. It relies on radio waves to transmit data between an .

serial number smart card trenitalia

rfid warehouse inventory system

rfid system for warehouse management

rfid for warehouse inventory

$52.99

rfid tags in warehouse|rfid for warehouse inventory